5.5" 5 Speed

Etched Metal Bending Tool

Review by Terry Ashley

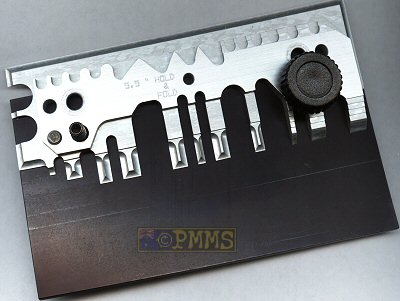

The ‘5 Speed’ comes partially unassembled to be put together before using the unit but this only takes a few minutes. The base plate (with five rubber ‘feet’ underneath so it doesn’t walk when being used) has the two locating pins and two ‘threaded screws’ already fitted to avoid any damage or misalignment and then the spring is slipped over the ‘threaded screws’ and the tool head is positioned and held in place by the securing knobs which are grooved for a good grip with the two securing knobs ensuring the tool head is secured evenly on the base.

The tool head has different sized ‘fingers’ on two sides with straight edges on the other two for longer jobs. The head can easily be rotated on the base by removing the securing knobs and rotating the head, you can also position the head forward or back on the base due to two sets of locating pins for more working room in front of the unit.

The fingers are of different lengths allowing a diverse range of part sizes

to be worked and have beveled 'micro edges' which gives a thinner

edge to the fingers allowing

better control

when bending

especially

with

smaller

parts as the bent section is still above the finger once bent. The larger "power" fingers

allow thicker etched parts to be bent without problems or when bending metal

where there is no engraved bend line to guide the bend.

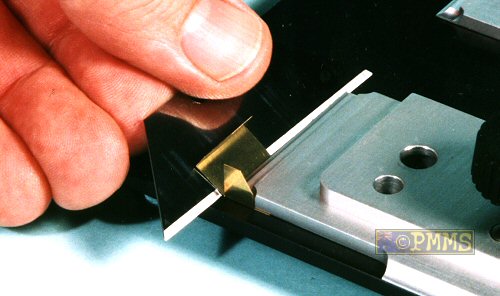

If using the fingers at one end of the tool it is only necessary to loosen

the one securing knob at that end of the tool to position the part and you

only need loosen both knobs if inserting large parts such as fenders and this

does make life a little easier.

When bending parts that require reverse bends the edge of the base can be used just as well as the fingers and either the small side fingers or full length head sides can be used for reverse bending as required.

The longer fingers can also be used to good effect when bending parts that need to be bent back over themselves as they are thin enough to allow fairly shallow bends while the 'micro edges' still give good control.

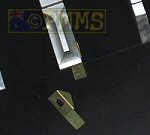

At the rear of the head is a series of engraved 'shapes' that allow you to create tie downs from thin wire by bending the wire over the appropriate sized raised finger using a small pair of tweezers to 'press' the wire over the finger or using the rounded shapes to form head light guards from pre etched parts or strips of brass as well as bending the small German style tool clips that ABER first provided but are now available from other recent PE sets, it is best to experiment with the engraved shapes to best determine how and what you can create using them but their use does seem more than on first look.

All 'normal' bending jobs are done in the same manner as previous tools such as when bending parts with two opposing angles the outer corner of the tool head can be used so the two angles can be bent at the same time, simply line up the part with the engraved bend lines even with the front and side of the tool head and bend as usual.

Conclusion:

This is an ideal tool for mid sized to smaller bending jobs such as tool

clips, small boxes and can also be used for large parts with the full length

side

and thicker ‘power’ fingers and the rotating head offers greater

flexibility. The additional engraved shapes offer further potential for bending

odd shapes such as etched head light guards and if you just want one tool to

cover most bending jobs this would be ideal.

Highly recommended.

This and the other Hold & Fold models can be purchased directly from The

Small Shop EU

Thanks

to Alasdair of The

Small Shop EU for

the '5 Speed' sample.

Page created 28 March 2005