ETCH MATE

Etched Metal Bending Tool

#EM-001

Review by Terry Ashley

Some of the etched sets produced today by the likes of Eduard, ABER, Part and others plus new players such as Gum Ka and Lion Roar from Asia are of a high quality and some of these are more like exercises in precision engineering to assemble.

I have always got by using two steel rulers held together by strong spring clips when bending these parts and the obvious limitations of this method has made for some interesting situations.

It was only a matter of time before a dedicated tool was produced to handle this job and alleviate my misery.

One such tool is the Etch Mate from Mission Models which I have just received, I have also recently acquired two other types of bending tools, one the Hold & Fold and the other a locally produced item and while this isn’t a comparison review I will make some quick comments on these at the end of this review.

Each tool uses the same basic principals of design just like a pair of scissors, tweezers or claw hammer but offer different or additional features to make them different and the job easier.

So to the Etch Mate, it arrived in a sturdy cardboard box just the thing

for it to live in during its life.

The base plate measures 165mm x 90mm x 6mm (6½” x 3½”

x ¼”) and a top section with six bending “fingers”

of different widths and generous spaces between the fingers for different bending

jobs.

Both the upper and lower parts are finished in a nice anodised greenish finish

to give the whole unit a professional appearance.

The top bending part is held in place by four locating “pins” and a central screw pin with a turning handle, this is an easy to grip handle and not a round knob as on the other two (opps I’m comparing, sorry).

This central screw pin also has a spring trapped between the top and bottom

sections which allow the top section to rise up with only small turns of the

handle and makes slipping in the etched pieces very easy.

To further ease the lining up of the parts, there is a small triangular folding

channel engraved into the lower plate, this allows you to line up the etched

parts precisely before lowering the top section and also assists in producing

accurate bends. The top section also has steps included in the bending fingers

to allow for smaller and intricate bending jobs such as parts with multiple

bends. This top section can also be reversed to use the full length back end

for bending large parts such as fenders or the like.

Finally you are provided with four self adhesive “feet” to attach

on each underside corner for a slip free sit on your workbench and a razor blade

to use when bending the etched parts. I must give a word of caution here for

while the Etch Mate isn’t a cutting tool the razor blade is just

that, a razor blade and a sharp one at that. Extreme care should be exercised

when using this so as not the slice you fingers and when not in use a safe home

should be found.

I use a section of plastic pencil eraser and press the blade into this to keep

it out of harms way.

The instruction sheet is a single letter sized page with a general description of the Etch Mate and detailed instructions on using the tool; you should read these before starting work.

So it all looks nice but does it work?

For this exercise I have selected the fender grouser box from the new Marder

IIIM Eduard set (#35 528) and after removing the part from the fret and

cleaning up any burs with a fine file in the usual manner we are ready to start

bending.

One thing this or any bending tool will not do is decide the bending sequence of the part; you have to work this out yourself if the kit instructions don’t tell you. Ascertain the most appropriate sequence bearing in mind it can get tricky once you have made a few bends.

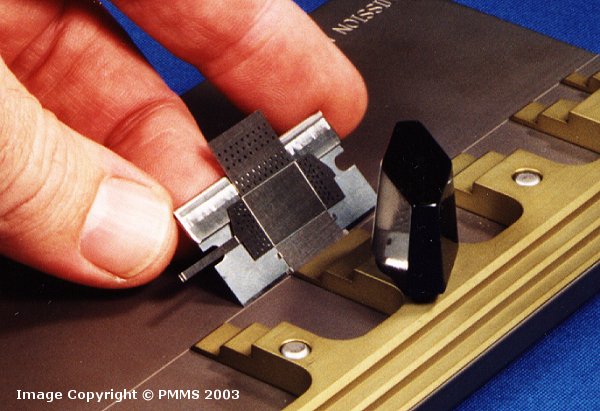

Loosen the handle to allow the bending head to rise (I love that spring loading) and slip the etched part under the head to line up with the engraved line on the base and tighten the handle. When in the correct position give the handle a final turn to hold the part firmly in place. Next slip the razor blade under the etched part and gently raise this to bend the part, note how the blade tip sits into the engraved line to make a perfectly square bend.

Next loosen the head and reposition the etched part for the next bend, from

here on you have to take into account where the previously bent sections will

end up after the next bend, it may be better to move to a finger away from the

tightening handle?

When the next part is secured in place, repeat the bending process as above.

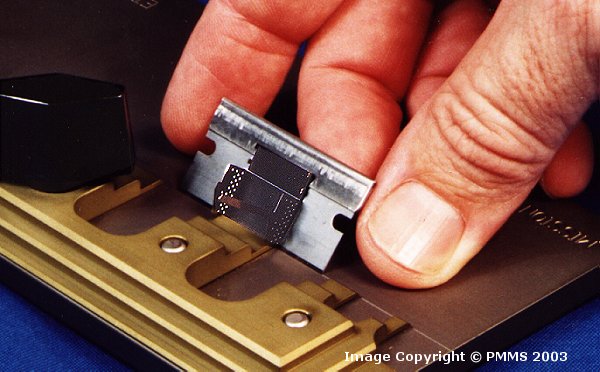

Continue to reposition the part for further bends, again notice how the blade edge sits firmly into the engrave line to ensure the bend is accurate and square.

After bending the two sides you have to position the part on a smaller finger to allow the sides to slip unhindered past the finger as you bend the part to form the box.

The finished box achieved quickly and without any problems, the Etch Mate makes the job extremely easy, there is another tool I use which is invaluable for simple bends and handling the etched parts, this is a pair of snub nosed tweezers and used in conjunction with the Etch Mate it seems they were made for each other.

Conclusion:

In all an excellent tool which does its designated job simply and efficiently,

a couple of the features on the Etch Mate such as the stepped fingers,

spring loaded tightening handle and engraved bending line really help to make

the tool perform very well.

This will become an essential tool for the modeller no matter what their subject

type; I know I will be making very good use this tool.

Highly recommended.

Thanks to Jon Tamkin of Mission

Models for the Etch

Mate.

Visit the Etch Mate

Website for details on ordering.

Also see the 6.5 & 4.5 Extended Folding Blade set to compliment the Etchmate.

Comment

on the other tools:

Just a quick comment on the other two tools I have; one a local product in very

basic and while it will bend etched pieces it is crude compared to the other

two.

As to the Hold & Fold, well I can’t say much because the original

unit I had at the time of this review is faulty; the lower plate is warped

so the upper bending plate will not align

correctly making securing the etched pieces for bending almost impossible.

Unfortunately the makers weren't too helpfull with this problem at the time

but Hold & Fold have

now released updated versions of their tool where the above problem has

been

addressed.

Page created 28 January 2003

Updated 28 March 2004