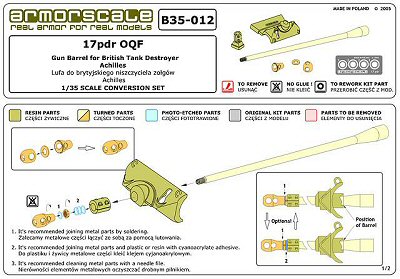

17Pdr OQF

barrel for British Achilles

Armorscale 1:35th Scale Set No. B35-012

Review by Terry Ashley

Armorscale continue to add Allied subjects to their range with

this replacement

barrel designed for the Academy 17Pdr Achilles (Kit #1392)

which consists of the distinctive Achilles resin mantlet and bolted counter weight,

a turned metal

barrel which includes rifling with a three part formed brass muzzle brake and

four etched spacer rings.

Armorscale continue to add Allied subjects to their range with

this replacement

barrel designed for the Academy 17Pdr Achilles (Kit #1392)

which consists of the distinctive Achilles resin mantlet and bolted counter weight,

a turned metal

barrel which includes rifling with a three part formed brass muzzle brake and

four etched spacer rings.

The standard of resin casting is excellent with subtle cast texture and well defined weld seams on the mantlet which also includes the two upper lifting rings in the casting. Apart from the large casting blocks and some thin resin film inside the lifting eyes there is no other cleanup required on the parts. The counter weight has a hole through the middle which opens up when the casting block is removed and the barrel hole through the mantlet is also cleanly formed.

The bolt head detail on the counter weight is also very well defined with the hole a perfect size to fit the metal barrel as is the hole through the mantlet.

The brass muzzle brake is split in two parts with an inner flange ring as well as a brass collar with an etched spacer ring between them, there are also three optional spacer rings that can be added between the brass collar and resin counter weight as this is sometimes fitted a little further back on the barrel.

As with previous Armorscale barrels the barrel tip is threaded and the muzzle brake simply screws in place negating the need for gluing and ensures a secure fitting. You have to make sure the muzzle brake holes and bolt orientation on the counter weight line up after screwing the muzzle brake into position, which isn’t a difficult task.

The shape of the muzzle brake contours and holes as well as the barrel length match exactly to 1:35 plans in Ground Power No.81 Feb 2001 and Wyndawnictwo Militaria No. 114 M10/M36 with the mantlet also matching in all dimensions except the width which is 1.5mm narrower than on both sets of plans. The mantlet is also narrower than the Academy kit mantlet width which it is designed to replace and although the detail is better on the resin mantlet the width raises other issues.

With the barrel in the mantlet slip the counter weight over the barrel without gluing at this stage and then add the required number of spacer rings for your barrel, you may have to slightly enlarge the inner diameter of the etched rings to fit the barrel with a fine file and it is best to do this while they are still attached to the fret for easier handing.

The rear brass collar isn’t threaded and simply fits over the barrel and again this may have to be slightly filed to fit the barrel.

Assembling the muzzle brake is straightforward by fitting the inner ring inside the forward half and then fitting the front and rear sections of the muzzle brake together. The fit of the two muzzle brake halves is very precise leaving only a very fine join line to be eliminated with soldering being the best option here.

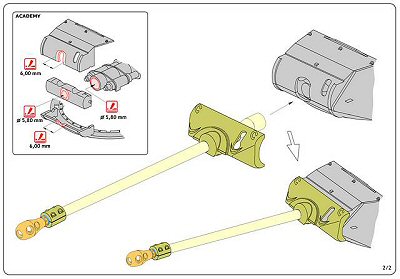

Fitting the assembled barrel/muzzle brake requires some minor alterations to the Academy kit but nothing difficult. The barrel locating hole in the gun mounting (part E3) has to be drilled out to 6mm and the openings in the front of the turret ring and upper support (parts G3 and E7) also need enlarging to 6mm, the instructions again show these alterations. The barrel/mantlet assembly then fits to the Academy turret without further alterations.

to the gun mounting, Academy mantlet is replaced entirely

Inner muzzle brake ring fitted to the outer muzzle brake half

The new barrel/mantlet could be used on the AFV Club Achilles with only a minor alterations to the kit gun mounting but as the AFV Club mantlet is some 4mm wider then the Academy and Armorscale mantlets it would look way too small on the kit.

Instructions

Recommended.

Thanks to armorscale for the review set.