Panzer 1A Sd.Kfz.101

Tristar Kit No. 35003

1/35 Scale

Construction Review by Terry Ashley

I will basically

follow the construction sequence and highlight any problems along the way; I

have also added additional details from plastic card, rod and bits from the

ABER Pz.Kpfw.1 detail set (No.35065) and will explain these also.

It should be noted that the ABER set is designed for the Italeri/Zvezda

Panzer 1 and as the detail on the Tristar kit is far better than these

kits not all the ABER bits are needed.

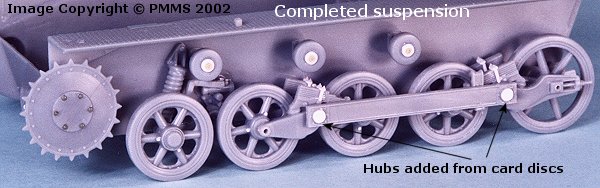

Suspension

and Drive Sprockets.

The kit parts are

nicely detailed and fit together well, by following the instructions you shouldn’t

have any problems.

I felt some areas could do with some tweaking and started with the road wheels,

these have the lubrication points included but I added a small plastic card

disc (made with a punch and die set) to make then stand out a little more.

On the main suspension units I cut off the leaf spring securing bolts which

were a little underdone on the kit parts and replaced these with plastic card

and rod with Grant Line bolt heads for better definition and also drilled

out the centre of the axle hubs as these are hollow on most photos I’ve

seen.

The return rollers

hubs have a raised centre section and I added this with more plastic card discs

with an etched ‘bolt’ centre.

The main bolts on the drive sprockets I also felt were a little small and I

replaced these with larger bolt heads taken from and old Tamiya M3 Lee

kit.

These old kits such as the M3 Lee and M3 Stuart which have many bolt heads included are excellent for cannibalising by cutting of the bolt heads with a shape blade and using elsewhere by attaching them with a small dab of liquid cement. One kit can supply you with hundreds of bolt heads of different sizes.

Finally the beam

between the two suspension units also should have raised ‘hubs’

where they attach to the units and again these were added using plastic card

discs.

The road

wheels are designed to rotate freely, but I glued these in place to aid in attaching

the tracks and also to ensure the added details remained visible.

Hull

Construction:

This is fairly

straightforward with only a few parts to make the hull proper. On the lower

hull is added the front plate which fitted nicely but take care to put it the

right way up with bolt heads to the bottom, this part will fit either way so

take note. The rear plate fitted without problems and there is also an internal

bulkhead to add. This can’t be seen after construction but does give some

rigidity to the lower hull but I don’t think it would cause a problem

if left out?

The upper hull is one large moulding but ensure you add the rear intakes grills

(part C13) from the inside of the upper hull before gluing to the lower

hull or you will have some fun fitting the grills.

I glued the main upper hull to the lower hull before added the front glacis

plate (part C19) as this had some minor fit problems. I had to trim small amounts

from both sides and the front to get a good fit between the front plate and

upper hull.

Trim small amounts only and test fit often, don’t trim too much at one

time because it’s a bigger problem to add some back if the plate is trimmed

too small.

All the hull hatches and vision ports are separate parts so you can choose to

show these open or closed?

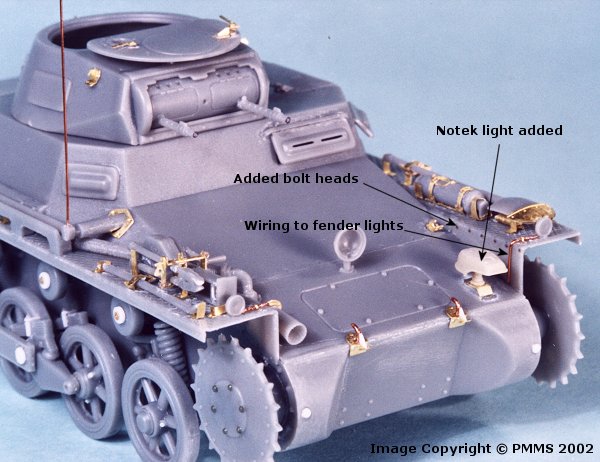

I added a row

of six bolt heads along the rear hull sides (behind the exhausts) as these were

missing but would be impossible for Tristar to include given the constraints

of the injection moulding process. These bolts were again ‘stolen’

from the old Tamiya Lee kit. They are very small and partially hidden

by the exhausts so may not be noticed on the finished model?

Another six small bolt heads were added inside the front fenders also using

the same method as above but are more noticeable than the rear bolts.

Wiring was added to the small front fender lights from thin wire and the Notek

light was added with a resin light from a Royal Models set on an etched

base made from a bit of left over brass. The Notek light was often fitted to

later vehicles as well as most Afrika Korps vehicles and as I will be finishing

the model in that paint scheme I decided to add this.

The rear exhausts were hollowed out by careful drilling and trimming with a

sharp blade as well as the right front outlet pipe being drilled out and the

aerial was repositioned in the up position with the aerial itself being replaced

with thin wire.

The plate fitted over the rear engine grills was thinned at

the edges for better effect as were the front section of the side fenders as

I left off the front fender extensions (these are rarely seen on operational

vehicles).

On the rear hull the towing shackle was thinned down for a more realistic appearance

and an etched chain added (not shown in photos).

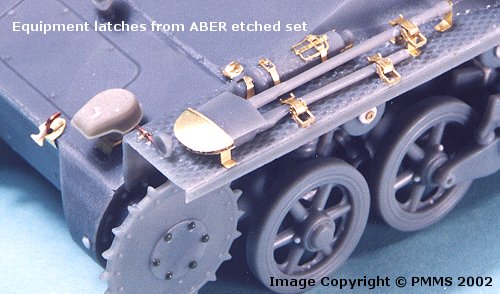

This completes the main additions to the hull; all the remaining detailing was

replacing some kit parts with items from the ABER etched set. These included

all the lifting points with the two hull front points being further detailed

with bits a thin card and wire. The front klaxon horn mount was replaced as

were all the tool attachments and latches. These latches are fairly time consuming

but do add to the final appearance, one thing I have noticed with the ABER

tool latches in they appear to be slightly over sized? I have noticed this on

other models I’ve added these bits too but is more noticeable on such

a small vehicle therefore I reduced some of the latches in size to better fit

onto the fenders.

The tracks and lens from the large front light were left off until after painting.

The

Turret:

This again is very

simple in construction and went together without any problems. I drilled out

the MG barrels and added the lifting points from the ABER set as well

as the internal latches on the separate main hatch.

When drilling out barrels I find it helpful to mark the end of the barrel with

a black felt pen, this gives a better key to ensure your drill bit is centred

before drilling, nothing worse than drilling a hole only to find it if off to

one side. (see image above)

The vision ports are again separate so you can position these open if you wish?

The

Tracks:

These tracks by ModelKasten are sensational and are specially made for this

kit. There are left and right hand tracks so take care when assembling to ensure

you use them on the correct hand.

The instructions show to lay the links out on a piece of self

adhesive tape and insert the connecting pins as you go. While this method will

work perfectly well I personally prefer another method for assembling separate

track links.

After removing the links from the sprues (and taking care of any cleanup needed?),

I assemble a short length of track (say 10 links) by holding the links between

my fingers, clipping the next link in place and inserting the connecting pin.

Apply a small amount of liquid cement to each connecting pin and cut off once

dry. Doing this in short lengths avoids a long length dangling out of your hand.

When you have enough short sections for one track, 8 in this case as there are

88 links per side; you can then join the shorter sections together to form the

one full track length.

As is said this is a personal preference and the tape method plus the use of

a custom made jig will also work, whatever method works best for you is the

one to use.

Return to the First Look review of the Panzer 1A with images of the Sprues, Decals etc.

Also see Brett

Green's building of this kit on Hyperscale:

Part

1 Construction

Part

2 Painting and Finishing

|

Panzer Tracts No 1-1 |

Panzer Tracts No 1-2 |

|

Ground Power Magazine |

Pz.Kpfw.I/Pz.Kpfw.II and variants |

| TANKS & ARMOUR: PanzerKampfwagen 1 & II Ian Allen Publishing

|

AFV Modeller Issue 12 Excellent photo feature on the Panzer 1a  |

|

Military Modelling Magazine |

|

Page created 10 September 2002

Updated 14 September 2002