The EASYbend follows the same basic design principals as all other hobby etched bending tools except the Ausfwerks Designs Fender Bender in having the base plate and top bending plate with a series of different sized bending ‘fingers’ as well as one long straight edge on the opposite side of the bending plate. But unlike other contemporary tools currently available it is made of anodized steel for a sturdy and robust tool not prone to some of the durability issues with tools made from other mediums.

The EASYbend measures 150mm x 100mm x 6mm (6 7/8” x 3 15/16” x 3/16”) with the top bending plate having six stepped bending “fingers” of different widths and generous spaces between the fingers for different bending jobs and comes fully assembled including the lower plastic “feet” so there is no need for any assembly. Also included in a standard safety razor blade for bending the etched parts and small instruction sheet that gives tips on using the tool for those not familiar with these.

The top bending plate is held in place by two locating “pins” and a central sprung screw pin with an easy to grip tightening handle that allows the top bending plate to rise up with only small turns of the handle and makes slipping the etched pieces in place very easy.

One feature of the design in the bending head in located centrally on the base plate which means you don’t need to unscrew and rotate the top bending plate when switching from the fingers to the full length sides and this virtually eliminates the need to actually remove the bending plate from the base during use.

To assist with the bending process there is are small folding channels engraved into the base plate along the front edges of the finger and full length sides that assists in lining up the etched parts precisely before tightening the bending plate. This also assists in holding the razor blade in place during the bend but I found the channel to be slightly too wide allowing a little movement of the razor and you have to apply pressure while bending to ensure the razor stays hard up against the etched part for a sharp bend.

A word of warning as with all other tools in that the razor blade is just that, a razor blade and a sharp one meaning you should take care when using this so as not the slice you fingers and when not in use a safe home should be found.

I use a section of plastic pencil eraser or balsa wood and press the blade into this to keep it out of harms way when not is use.

The instruction sheet is a single A4 sized page with general instructions in both English and Italian that includes a few images to illustrate the text.

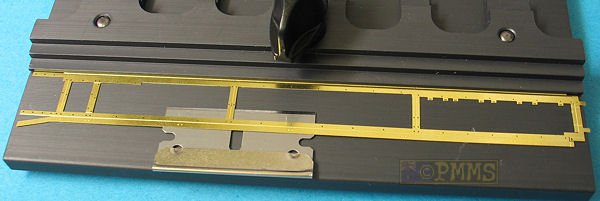

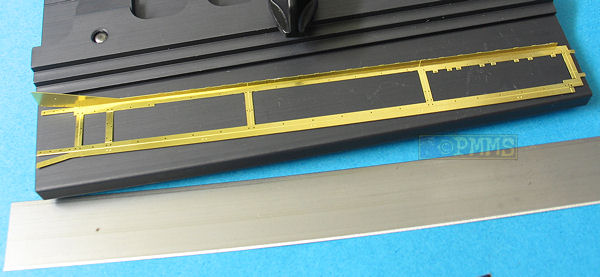

In testing the tool I have used the Voyager Models Panzer IV Fender Set #PE35145 which includes smaller parts as well as the full length fender bends to fully test the EASYbend capabilities.

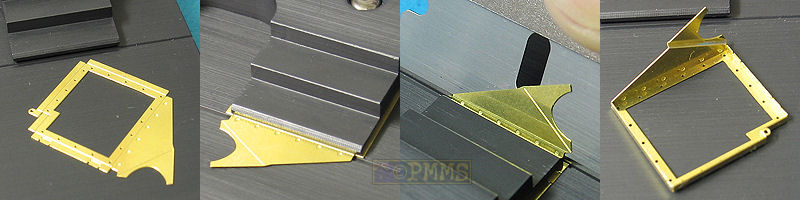

One thing with this or any bending tool is to decide the bending sequence of the part; you have to work this out yourself if the kit instructions don’t tell you. Ascertain the most appropriate sequence bearing in mind it can get tricky once you have made a few bends.

Loosen the handle to allow the bending head to rise (made easy with the spring) and slip the etched part under the head to line up with the engraved line on the base and tighten the handle. When in the correct position give the handle a final turn to hold the part firmly in place. Next slip the razor blade under the etched part and gently raise this to bend the part ensuring you keep the razor pressed firmly against the etched part as above.

Next loosen the head and reposition the etched part for the next bend, from here on you have to take into account where the previously bent sections will end up after the next bend, it may be better to move to another finger or the ends of the bending plate to take into account the already bent sections.

When the next part is secured in place, repeat the bending process as above until you have the final part and as with other tools using a small pair of flat nosed tweezers for small tricky bends with help with the final result.

Example of bending the smallest of brackets without any problems

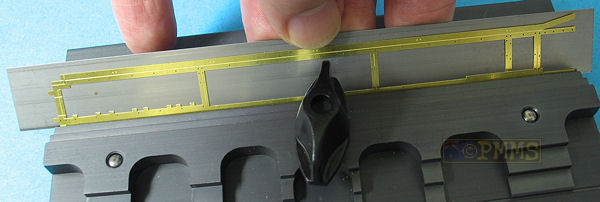

For the full length fender edges you just repeat the above but slip the etched fender under the full length side and as mentioned not having the remove and reposition the bending head does make this a lot easier.

There was one issue when bending the full length fender in that you only have the small standard razor blade which means you have to bend a short section of the fender at a time moving along until the full length is bent. This will work okay in most instances but where the etched part is quite narrow as with the Voyager parts there is potential for problems. There is a ready answer to this problem in the form of the Mission Models 6.5 Extended Folding Blade (set #EM-002) and I used this here to bending the full length fender edges a lot easier.

The Mission Models 6.5 Extended Folding Blade (set #EM-002) used to make the job easier

During the bending on the large and smaller parts the EASYbend bending head held the parts firmly in place even at the extreme edges with only moderate pressure on the tightening handle and this helps in eliminating part slip for better bends.

There is one issue that again is in common with all bending tools in that alignment pins can at times get in the way of larger etched parts meaning you have to use an alternate “finger” or realign the part to be bent but this is easy to work around in most instances.

Conclusion:

In all this is an excellent tool which does its designed job simply and efficiently with features found in most bending tools these days. The location of the bending head makes switching between the individual fingers and the full length edge very easy, especially on larger parts such as the fenders used here.

As mentioned the tool follows the same basic design features of many etched bending tools available today in the same way different types of airbrushes follow the same principals with minor differences as do many other hobby and full sized tools.

I found the tool held etched parts from the largest to the smallest firmly in place with just the width of the engraved channel requiring care to ensure the razor stays hard up against the parts during bending. It worked well in most jobs other than the most complicated where any tool would have problems and resulted in sharp and precise bends.

Highly recommended

The Easybend is available from the steelmodels.com website who also carry many other hobby product lines.

Thanks to Matteo of Steelmodels for the review set.