While the sets are labeled Early, Mid, Late there is no distinct delineation between the introduction of each muzzle brake type and the three types can been seen at overlapping time periods depending on the vehicle they were used on so the names are basically just to differentiate between the sets.

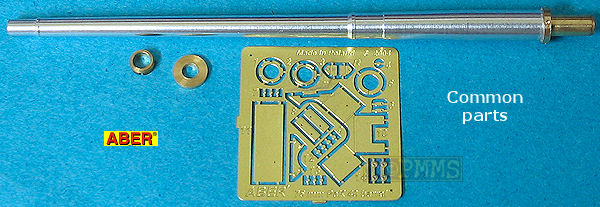

Each barrel is made up of the full length barrel in aluminium with rifling included in the drilled out muzzle plus 4 brass and 27 etched parts for the muzzle brakes and barrel mounting.

Dimensionally the barrel length matches available data and the 1:35 plans in the Nuts & Bolts book below it should be noted that the 1:35 plans in the AGP book have the barrel length considerably less than it should be which may cause some confusion. One interesting point is while the length matches the plans the position of the central cradle attachment strip bracket is fractionally further back than the Nuts & Bolts plans indicate. But the barrel contours match all available kits and are designed to fit the kit cradles without any alignment problems and the small discrepancy wouldn't be noticed in any case unless you carry around a set of plans and calipers?

Common Metal and etched parts

Muzzle brake halves for the 3 types

Barrel rifling

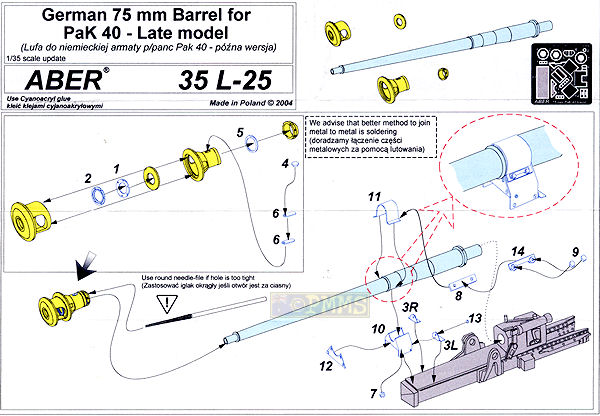

The rear muzzle brake half and the muzzle brake collar may need the inner locating hole slightly enlarged using a fine needle file to fit onto the barrel and the small etched ring between the rear collar and muzzle brake may also need to be enlarged slightly. This is best done while the part is still attached to the etched fret for easier handling or filing the end of the barrel to reduce the diameter may be a better option rather than enlarging the holes on the three separate parts. Test fit often while filing so as not to remove too much material.

When fitting the two muzzle brake halves together ensure the large openings are lined up correctly which may sound logical but if using cyanoacrylate and focusing on fitting the parts together these may be misaligned? After joining the two muzzle brake halves together there is a small join seam between the two that will need to be eliminated and soldering and lightly filing the join would be the easiest method to deal with this.

There is a small etched retaining bracket added to the top of the muzzle brake made up of three very small etched parts that will need care removing from the frets and fitting. You should also note the small bolt head goes to the back of the etched bracket and not the front as shown in the instructions.

You then slip the brass collar and etched ring onto the barrel and add the assembled muzzle brake to complete the barrel assembly.

Inner bearing added to forward muzzle brake half

note separate etched bearing rings to be fitted

Assembled muzzle brakes

Images of actual muzzle brakes (early, mid, late types)

Fitting the barrel to any of the applicable kits will need the barrel collar cut from the kit breech as most have this moulded with the breech, the barrel hole in the kit breech may have to be enlarged depending on the kit used and test fitting will determine this.

The barrel cradle mounting is also provided as etched parts that will need careful bending to shape before fitting to the target kit gun cradle. It is best to anneal the barrel securing strip by running the etched part through a candle flame to make bending around the barrel easier in eliminating the springiness of the brass part. The smaller etched parts can then be added to the mounting to finish off the assembly.

with just the muzzle brake parts being different

Overall these barrels which ever you choose match photos nicely and will improve the look of the target gun considerably over the plastic kit muzzle brakes.

Highly recommended.

See the PaK40 subjects page for additional reviews.

| Nuts & Bolts Vol.18 Marder III H & Pak40  |

carry

the full range of ABER update sets and barrels.

carry

the full range of ABER update sets and barrels.