15cm Panzerwerfer 42 (Zehnling) auf sWS

Bronco Models 1:35 Scale Kit No. CB-35070

Kit review by Terry Ashley

The sWS was powered by a 6 cylinder, water-cooled Maybach HL42 TRKMS gasoline engine generating 100 horsepower (75 kW) which gave it a top speed of 27 klm per hour (17.0 mph) on good roads with a load capacity of 4,000 kilograms (8,800 lb).

Later types featured an armoured cab and engine compartment looking similar to the Sd.Kfz.251 with fold down sides for the rear cargo bay. The armoured sWS was also used in two other configurations, one fitted with the 3.7cm FlaK 43 anti-aircraft gun on the rear bed and the Panzerwerfer 15cm Nebelwerfer 42 rocket launcher mounted over an armoured ammunition storage compartment built over the cargo area.

The sWS 15cm Nebelwerfer 42 was fitted with the 10 barrelled 15cm rocket launcher assembly from the earlier SdKfz.4/1 Maultier armoured halftrack mounted on the rear armoured sWS body but production numbers if any of the sWS 15cm Nebelwerfer 42 are not clear with only one period photo available of a vehicle captured by the Allies later in the War.

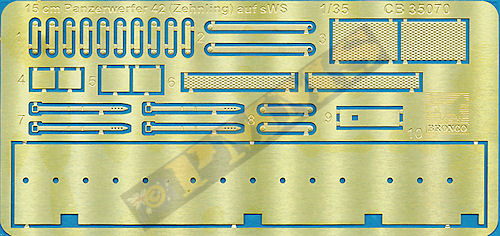

The kit has 536 parts with another 248 individual track links in light beige plastic plus 28 etched parts. Added to this are the decal sheet and 16 page instruction booklet and a colour painting guide sheet.

The quality of the moulding is excellent with clean crisp details virtually free of any flash or pin marks and any present is quite minor and easily dealt with. There are the usual mould seam lines to be removed and as some of the parts are extremely small and you will need to take care removing these from the sprues and during assembly.

Dimensionally the kit measures up very well against the 1:35 plans in the Tank Magazine and Panzer Tracts books listed below. There is also disagreement on some dimensions between the plans with the kit matching parts of one plan but not on the other plans and visa-versa. So overall things sort of even out and the kit doesn’t look out of proportion when compared the available photos.

Included in the kit are a number of options including two styles of front wheel rims, the initial large and later smaller diameter drive sprocket as well the initial spoke idler and the solid disc idler plus a full set of full dish road wheels.

The kit is also broken down into sub-assemblies which can be built separately and brought together at final assembly which allows you to work on one while the glue/paint dries on another and this helps speed up assembly. The sub-assemblies are the lower chassis/suspension, forward cab/engine compartment, rear armoured compartment and the 15cm Nebelwerfer.

These channels fit neatly inside the chassis without any problems and there is also a three part fuel tank, a couple of bulkheads and two air tanks added inside the chassis. Included in the kit are the multi-part winch and cable guide assemblies but the armoured sWS versions did not have the winch fitted so you shouldn’t fit these parts. Considering some of these chassis parts can't be seen after the rear tray is fitted you could probably save yourself a bit of work by not fitting some of the parts, it’s your choice.

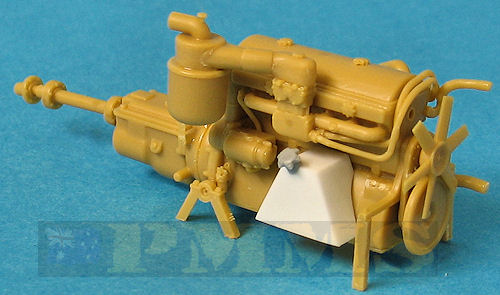

The kit includes the full Maybach HL42 TRKMS engine and transmission to fill the engine bay but unfortunately the engine as supplied doesn’t represent the Maybach HL 42 TRKMS engine at all well with some work needed to accurately portray theengine.

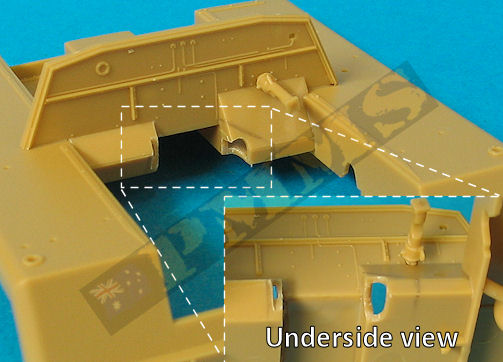

The sWS didn’t have an open engine bay with the bottom of the bay fully enclosed to prevent debris entering the compartment and the large square and smaller round holes will need to be filled in the kit compartment floor before proceeding.

The major engine alterations are the underside oil pan (part J2) should be basically flush with the bottom of the engine block and not extend down as supplied; this extended oil pan configuration is for the Maybach HL 42 TUKRM fitted tothe Sd.Kfz.11/251 series vehicles.

The top valve cover (part J1) should only had the two smaller “star” filler caps and not the central raised filler cap and this will need to be removed and there should be a large triangular shaped oil tank added to the right side of the engine. The rear clutch cover (parts J11, J17) represents that of the HL 42 TUKRM requiring modifications to represent that of the HL 42 TRKMS.

Other alterations include eliminating part J28 (note this is labelled L28 in the instructions) which in turn means you have to remove the corresponding fan belt and pulley form part J33 designed the mate to part J28.

Apart from the alterations to accurately portray the HL 42 TRKMS the remainder of the engine is highly detailed with all the accessories such as alternator, carburettor, fuel pump, fan, belts with pulleys etc. as well as the large air cleaner, intake and exhaust manifolds with their connecting pipes all included as separate parts.

At the front is a five part radiator assembly that connects to the engine by two large radiator hoses and a four part gearbox case added to the rear which connects to the transfer box and transmission with four ribbed brake discs for a very detailed and impressive assembly that fits neatly into the chassis bay.

The separate exhaust pipe fits to the exhaust manifold to mate on the inside of the chassis level with the outer exhaust pipe and muffler, unfortunately the inner exhaust pipe fouls on the steering rod (part B36) when fitted and I had to cut and reposition the exhaust pipe to miss the steering rod, again not a big adjustment but a little annoying.

As mentioned the armoured sWS versions don’t have the winch fitted and apart from leaving out the main winch assembly and rear cable guide the large crew step (part D17,D18,D19) has to be relocated further outboard than indicated as it will foul on the towing pintle if fitted as intended, this is easy to do after filling the small holes.

Added to the chassis side are the five axles per side which have subtle cast texturing on the arms and you have to be careful removing the moulding seams so not to eliminate the texturing, the arms are hidden by the road wheels anyway so it probably doesn’t matter a lot?

The axle arms have a small pin to ensure they are all aligned correctly in the neutral position and if you wanted to articulate the suspension you just cut off the pin and reposition the arm.

At the back the idler axle mounting has a separate threaded adjustment bolt that fits through the hull bracket with a separate tensioning bolt and gives very good definition to the mounting, you may want to leave the idler axle unglued as some minor adjustment may be needed to allow the tracks to fit properly later.

There is also a three part towing pintle, boarding step and compressed air valve as well as the towing pintle on the front of the chassis with separate pin.

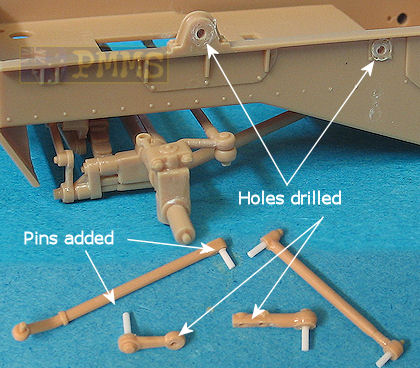

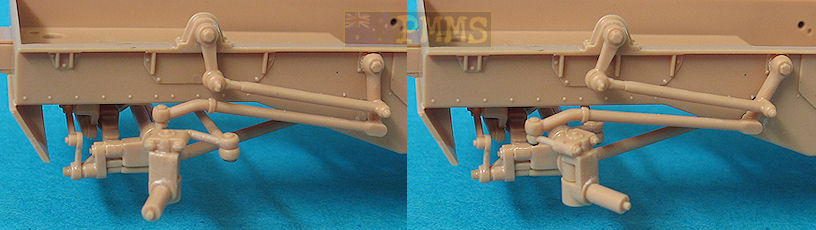

There are 4 steering linkages added to the left side of the chassis and these are not designed to be movable and once glued in place negate the workable steering?

This does allow you to position the front wheels at any angle as you glue the linkages for a bit of animation and it’s also a simple task to modify the steering linkages to make these workable for truly workable suspension if you wish.

This entails cutting the locating pins from the parts to fill the corresponding locating holes and when dry drill holes for the thin plastic rod pins (I used 0.6mm plastic rod) added to the appropriate places on the linkages. You then slip the pins through the holes and secure by heat melting the ends of the pins which results in fully workable steering.

This entails cutting the locating pins from the parts to fill the corresponding locating holes and when dry drill holes for the thin plastic rod pins (I used 0.6mm plastic rod) added to the appropriate places on the linkages. You then slip the pins through the holes and secure by heat melting the ends of the pins which results in fully workable steering. See images.

Holes drilled in chassis and linkages to take the pins added to the rods.

The pins are heat welded to secure in place.

Note; the locating pins are cut from the parts and glued into the locating holes before

drilling the pin holes.

Modified steering linkages allow for full movement.

Steering with wheels added

Another simple option is to assemble the steering as per instructions but to cut the pin from the front end of steering rod (part B20) and don’t glue the rod to part B10 on the axle assembly. This will allow the wheels to “steer” but the chassis side steering rods will remain fixed.

The front wheels have alternate hubs with subtle differences in the details such as rim bulge and number of lightening holes with both types seen in photos of the sWS so there is no real preference here as either can be used. The tyres are in six “slices” each which are sandwiched together for excellent representations of the tread pattern but you have to ensure the segments are put in the right order and also you should squeeze these together tightly when gluing to eliminate any gaps.

The hubs are a nice tight fit inside the tyres when assembled with the final wheels looking excellent with the well defined tread pattern; the only thing missing is any tyre side wall embossing but apart from that are very well done wheels.

Each drive sprocket is made up of three plastic parts and care is needed to clean up the mould seams inside the outer disc spokes and you need to watch the tooth alignment when gluing the inner and outer sprocket discs together.

There are two locating pins between the two sprocket halves and you should test fit these as the teeth only align with the pins one way, if you fit the pins the other way the teeth don’t align so make sure you get the two dish halves aligned correctly before gluing.

Added to the sprockets are etched step rings around the central hub with these having tread plate texturing on both sides for a good impression. It’s best to bend the etched part around a suitably sized drill bit shaft and join the end with a dab of cyanoacrylate. These can then be added to the sprocket hub with the fit being spot on making for a snug fit and this adds excellent definition to the sprocket hub.

As mentioned there two sizes of drive sprockets supplied in the kit and the majority of reference photos of the sWS show the larger sprocket with only one shot I found with the smaller sprocket. This does show both were used but it appears the larger is far more common, it also looks better IMHO.

The recent plans in the new Panzer Tracts book No.22-3 mittlerer Zugkraftwagen 5t (Sd.Kfz.6) and Schwerer Wehrmachtsschlepper indicate the larger drive sprocket is a little over 1mm too small in diameter, this doesn’t sound a lot but could be the reason the Friulmodel metal sWS tracks (Set # ATL44) don’t fit well due the smaller tooth pitch on the undersized diameter sprockets. If you use the kit tracks this won’t be an issue so I guess it’s up to the modeller if this is something to worry about.

The road wheels are the early solid dish type with 5 small cut-outs and these are well done with excellent hub details and good dish profile. Assembly is quite straightforward but I did have to enlarge the locating hole on the inside of the outer wheel (parts A25) slightly to better fit over the end of the axles. You just need a couple of twists of a 1mm drill bit to enlarge the hole but be extremely careful you don’t drill right through the outer wheel hub in the process.

At the back are alternate 2 part idler wheels, the initial spoke type and the later solid dish type with references showing the spoke type are more commonly seen so check if you are building a particular vehicle as to the idler type used.

While the links are not workable they are large enough for you to drill and add a 5mm wire pin at each side to make them workable if you wished.

The engine firewall has details included on both the engine and cabin side with a separate horn on the engine side along with a separate instrument panel with decal dials, radio and small lever box with three very small levers added to the driver’s side as well as the three separate foot pedals and three gear levers for a fairly well populated compartment. The seats are in three parts each and the floor has subtle tread plate included and there is additional equipment added to the sidewalls such as junction boxes and an MP40.

The two forward visors have separate 4 part inner brackets which allow these to be positioned open or closed depending on your preference?

Added to the fenders are the pioneer tools with moulded on clips, the two front head lights with separate base and two part light, the width indicator posts with a mirror on the left post plus the Bosch and Notek lights with etched bracket and the width indicators to the outer fender.

Under the left fender is a three part exhaust muffler with the end of the short pipe hollowed out for a better appearance and two bumper bars are added to the front and the engine compartment shell is a one piece moulding with separate panels for the Driver’s visor plate, roof and the fixed and opening engine bay panels plus the large front armour plate.

There are two small armoured “wings” added to the front plate and you should test fit this to the engine compartment to ensure these are glued at the correct angle with all the panels fitted perfectly without the need for any trimming and the central engine doors can be shown open or closed if you wish to show off the engine?

One notable detail on the engine doors is the four large vent louvers on the left door are moulded open for a very good appearance although using a sharp #11 blade to open up the louver holes more will enhance the appearance better. The two part roof hatch is free of inner pin marks and can also be shown open or closed as can the driver’s visors as mentioned above.

The fit of the upper armoured cab to the lower fenders is very good with small locating pins resulting in no filler or trimming being required BUT you do need to trim some plastic off the firewall for the engine to fit with the instructions indicating where to trim. You don’t need to trim as much plastic as indicated and repeated test fitting and minor trimming will result in much smaller gaps appearing inside the crew compartment. The inner pedal plate (B46) acts to hide the gap in any case if you just cut away the bare minimum to allow the engine to fit, see images.

Other smaller details include etched brackets and plastic grab handles plus the roof mounted MG42 which itself is a nicely done with separate ammo feed cover, front bipod and ammo drum, but the available image of the captured Panzerwerfer 15cm doesn’t have the MG42 fitted.

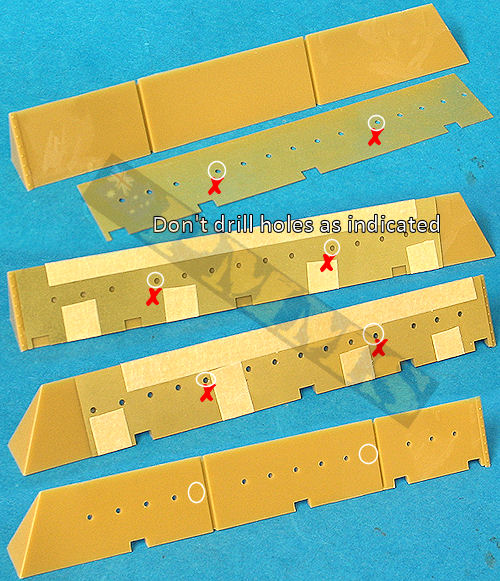

On the inside are the inner storage locker walls that also form the inside compartment walls but before gluing you need to modify the walls by drilling locating holes for the rocket brackets and the kit includes a large etched template for adding the holes and lower cut-outs. Firmly tape the template to the side panels before cutting out the lower recesses and drilling holes, note two holes on either side don’t need to be drilled, see image for this.

The rocket mounting brackets can be fitted in the open or closed position depending if a rocket is fitted to the rack, but take note you only get 20 rockets in the kit and if you plan on fully loading the launcher tubes that only leaves 10 rockets to add to the hull racks.

The fit of the compartment walls is very precise due to the large locating ribs but it is very important to fit these precisely as this will affect the final fit of the rear and roof plates, the rear panel has the two entry doors separate and these have additional small handles added and again these can be shown open if you wish but it’s probably best to leave these closed.

The fit of the rear plate to the assembled compartment was good but this will depend very much on the fitting of the side walls as mentioned so test fitting the rear panel while the side wall glue is still tacky would be an advantage for the best fit.

The roof has separate twin hatches forward and aft of the turret ring and these have inner latches as well as being free of pin marks should you want to show these open. Note that all hatches would be closed when firing the rockets due to the back blast if building the model in firing mode.

Fitting both the armoured engine compartment/cab and rear armoured superstructure to the lower chassis is very straightforward with a good fit not requiring any trimming, just ensure these are aligned correctly with the chassis as there are not actual locating lugs or pins.

On the outside of the turret are the large launcher mounting arms and smaller fittings including the etched vision port doors which can be shown open or closed as required. The articulated elevation arm is best left off until you fit the launcher assembly later.

The launcher has the top and bottom row of 5 tubes mounded as two single units with nice crisp details, the only real issue being the tube walls themselves are rather thick but they also include the inner rail detail so thinning the tube walls will also eliminate this detail.

The two 5 barrel mouldings fit together precisely with the fine electrical ducting fitted top and bottom supplied as separate parts, these do need extreme case when removing the fine mould seams and it’s best to do most of the cleaning while the ducting is still on the sprues for easier handing.

You also have to watch the ducting placement as all 10 are numbered differently depending on their location, so take this slow and check the instructions to fit these correctly first time. Small connecting junction boxes are then added on either side of the mounting as well as the rear plate with rocket opening which is another excellent moulding. Added to the rear plate are a further 20 small brackets for the firing contacts and securing latches which need care due to their small size.

If loading the rockets make sure you align these correctly with the rear openings as they can be pushed further into the tubes than they should go and the small firing ducting (parts R6) shouldn’t be added till after loading the rockets to get these aligned correctly with the rocket bases.

The fully assembled launcher assembly is quite impressive with the separate electrical ducting and small rear brackets and the launcher tube assembly can be elevated as required with the elevation arms (parts S8, S32) positioned accordingly. You also get etched alternatives for the elevation arms but given the extra work and the fact the plastic arms have more detail (bolt heads) I don’t think there is much to be gained in using the etched parts?

The launcher turret just sits in the roof turret ring and will come adrift if you turn the model upside down so just be aware of this after final assembly.

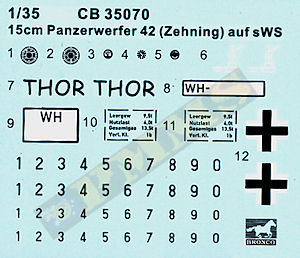

The two paint schemes are provided on the colour painting guide:

Option 1:

“THOR” in overall Dark Yellow with red brown and green cam scheme, the scheme is a subjective as it’s not clear from the available photo if the vehicle has cam applied or not? Option 2: “THOR” in overall Dark Yellow given as an alternative as it’s not clear from the available photo if the vehicle has cam applied or not?   |

The inclusion of the engine/transmission is a nice bonus even if some modifications are required to accurately depict the Maybach HL42 TRKMS engine it will still fill the engine bay should you wish to show the doors open or missing altogether as with the photo of the captured sWS.

The 15cm Nebelwerfer 42 rocket launcher is nicely done with a high standard of moulding and part fit although some issues such as the thickish tubes may need attention but overall it is a nicely produced kit that will look impressive once finished if reality is of no concern.

Rating: 8.5/10.

Click on thumbnails for larger view

Detail and assembly images

| Büssing's schwerer Wehrmachtschlepper (sWS), armored and unarmored variants Nuts & Bolts Vol.41  |

mittlerer Zugkraftwagen 5t (Sd.Kfz.6)

and Schwerer Wehrmachtsschlepper Panzer Tracks No.22-3  |

Halftrack Vehicles of the German Army 1395-1945 Schiffer Military History ISBN: 0-88740-758-7  |

German Medium Half-Tracked Prime Movers 1934-1945 Schiffer Publications ISBN: 0-7643-0263-9  |

for

the review kit.

for

the review kit.