Schwere Wehrmachtschlepper sWS

General cargo version w/5 crew

Great Wall Hobby 1:35 kit #L3512

Review by Terry Ashley

The initial unarmoured cargo version was produced by Büssing-NAG from December 1943 till the end of the war with a total of 825 produced; this was continuing post-war by Tatra in Czechoslovakia.

The sWS was powered by a 6 cylinder, water-cooled Maybach HL42TRKMS gasoline engine generating 100 horsepower (75 kW) which gave it a top speed of 27 klm per hour (17.0 mph) on good roads with a load capacity of 4,000 kilograms (8,800 lb).

The kit uses a couple of the sprues from the first kit (sprue A, B [with modified road wheels], K and chassis) along with new sprues for the cargo version cab and rear tray plus a set of five crew figures produced by Miniart. The other visual difference is the parts are now moulded in the usual gray plastic instead of the beige plastic in the first kit.

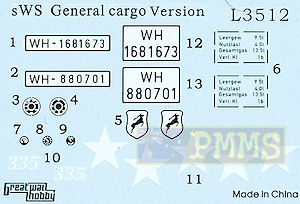

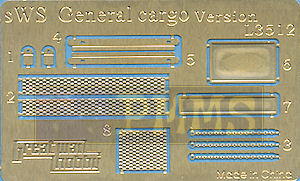

The kit has 337 parts in light gray plastic with another 472 individual track links in the same gray plastic plus 4 clear and 12 etched parts on 11 sprues and one metal fret. Added to this are the decal sheet and 11 page instruction booklet and a colour poster of the box art included which also has the colour painting guide on the back.

The quality of the moulding is excellent with clean crisp details virtually free of any flash or pin marks and any present is quite minor and easily dealt with. There are the usual mould seam lines to be removed and as some of the parts are extremely small and you will need to take care removing these from the sprues and during assembly.

Dimensionally the kit measures up very well against the 1:35 plans in the Tank Magazine and Panzer Tracts No.12 listed below with parts such as the running gear (apart from one issue as below), track and hull widths being spot on. There is also disagreement on some dimensions between the plans with the kit matching parts of one plan and parts of the other. So overall it sort of evens out and the kit certainly doesn’t look out of proportion in any way compared the available photos.

Included in the kit is a number of options including two styles of front wheel rims, two sizes of drive sprocket, the initial large and later smaller diameter sprocket as well as two styles of idler wheels, the initial spoke idler and the solid disc idler with the later style of road wheels which have the full dish wheels on the inside and spoke wheels on the outside of each wheel station.

The kit is also broken down into sub-assemblies which can be built separately and brought together at final assembly which allows you to work on one while the glue/paint dries on another and this helps speed up assembly. The sub-assemblies are the lower chassis/suspension, forward cab/engine compartment and rear cargo tray, plus of course the crew figures.

These channels fit neatly inside the chassis without any problems and there is also a detailed 5 part winch, 4 part fuel tank, a couple of bulkheads and two air tanks added inside the chassis as well as a 5 part winch cable guide. This guide has three very small roller wheels trapped between the two sides and removing these rollers from the sprue and fitting will really test you patience as well as eyesight. Considering some of these chassis parts can't be seen after the rear cargo bay is fitted you could probably save yourself a bit of work by not fitting some of the parts, it’s your choice.

Added to the chassis side are the 5 axles per side which have subtle cast texturing on the arms and you have to be careful removing the moulding seams so not to eliminate the texturing, the arms are hidden by the road wheels anyway so it probable doesn’t matter a lot?

The axle arms have a small pin to ensure they are all aligned correctly in the neutral position and if you wanted to articulate the suspension you just cut off the pin and reposition the arm.

At the back the idler axle mounting has a separate threaded adjustment bolt that fits through the hull bracket with a separate tensioning bolt and gives very good definition to the mounting.

There is also a three part towing pintle, boarding step and compressed air valve as well as the towing pintle on the front of the chassis with separate pin.

The remainder of the assembly is fairly straightforward but a little fiddly so take care to get everything in the right position and the assembled suspension unit then fits neatly into the locating holes on the bottom of the chassis.

There are 4 steering linkages added to the left side of the chassis and as we have seen on some other kits these are not designed to be movable and once glued in place negate the workable steering?

This does allow you to position the front wheels at any angle as you glue the linkages for a bit of animation and it’s also a simple task to modify the steering linkages to make these workable for truly workable suspension if you wish.

This entails cutting the locating pins from the parts to fill the corresponding locating holes and when dry drill holes for the thin plastic rod pins (I used 0.6mm plastic rod) added to the appropriate places on the linkages. You then slip the pins through the holes and secure by heat melting the ends of the pins which results in fully workable steering. See images.

The front wheels have alternate hubs with subtle differences in the details such as rim bulge and number of lightening holes with both types seen in photos of the sWS so there is no real preference here as either can be used. The tyres are in six sections each which are sandwiched together for excellent representations of the tread pattern but you have to ensure the segments are put in the right order and also you should squeeze these together tightly when gluing to eliminate any gaps.

The hubs are a nice tight fit inside the tyres when assembled with the final wheels looking excellent with the well defined tread pattern; the only thing missing is any tyre side wall embossing but apart from that are very well done wheels.

Each drive sprocket is made up of three plastic parts and care is needed to clean up the mould seams inside the outer disc spokes and you need to watch the tooth alignment when gluing the inner and outer sprocket discs together.

There are two locating pins between the two sprocket halves and you should test fit these as the teeth only align with the pins one way, if you fit the pins the other way the teeth don’t align so make sure you get the two dish halves aligned correctly before gluing.

Added to the sprockets are etched step rings around the central hub and these have tread plate texturing on both sides for a good impression. It’s best to bend the etched part around a suitably sized drill bit shaft and to solder the ends together for a stronger join, cyanoacrylate just won’t hold in this situation.

The soldered ring can then be added to the sprocket hub with the fit being spot on making for a snug fit and this adds excellent definition to the sprocket hub.

As mentioned there two sizes of drive sprockets supplied in the kit and the majority of reference photos of the sWS show the larger sprocket with only one shot I found with the smaller sprocket. This does show both were used but it appears the larger is far more common, it also looks better IMHO.

The road wheels have the solid dish type for the inner wheels and the 6 spoke type road wheels for the outer wheels which is the appropriate configuration as seen in some period photos. There are only enough of the solid dish road wheels for the 10 inner stations so you can't build the kit with a full set of solid dish wheels as seen in the promotional images.

There is a bit of cleanup needed on the spoke wheels to eliminate the mould seam on the spokes and the inner rim face which does become a little tedious but anyone having experience putting together Panzer IV or Churchill road wheels or similar will find these a breeze.

Updated 29 October 2009:

Additonal information received regarding the solid dish and spoked road wheel sizes is that they are in fact different diameters, this is due to the design of the steel wheel which incorporates an internal rubber damped rim while the solid spoke wheel has the rubber section on the outside. This indicates both types of wheels included in the kit are technically correct but unfortunately due to the fact the wheels are in plastic still results in a scale problem with the assembled suspension when translated from real size to 1:35 scale.

On the actual sWS mixed road wheels the compression of the outer rubber section of the solid spoke wheel due to the weight of the vehicle would see both sitting flush on the track surface. But unfortunately allowances for this compression is not replicated in the plastic kit wheels and you still have the steel wheel hovering above the track as shown in the images due to the difference in diameter of the wheels.

So while the kit wheels are technically correct, there should be allowances made for the scale effect regarding the compression on the solid dish rubber sections to allow both wheel types to sit flush on the track surface.

which while technically correct doesn't allow for the scale effects when applied to the model.

MR Models sWS wheel set #MRA-35302 (left) are shown for reference but these should be smaller

in diameter than the solid dish wheel.

The quickest remedy is to shave down the rubber section of the solid dish wheels to replicate the compression allowing them to sit flush on the track surface with the smaller diameter spoke wheels. The small discrepancies may not be an issue for some and having both wheels sitting flush on the tracks is better than not.

At the back are alternate 2 part idler wheels, the initial spoke type and the later solid dish type with references showing the spoke type are more commonly seen so check if you are building a particular vehicle as to the idler type used.

Detail on the track links is very well defined but there are some small pin marks on the inside of the alternate links without the guide teeth but these seem to disappear after assembly and are not at all obvious on the links I glued together for this review.

While the links are not workable they are large enough for you to drill and add a 5mm wire pin at each side to make them workable if you wished. Or if you have a set of Friul metal sWS tracks (set #ATL44) these should also fit as the Italeri sWS sprockets are the same size and tooth pitch as the sprockets in this kit.

The engine firewall has details included on both the engine and cabin side with a separate horn on the engine side and separate instrument panel with decal dials, radio and small lever box with three very small levers added to the driver’s side as well as the three separate foot pedals and two gear levers and the hand brake for a fairly well populated compartment. There are small sink marks on top of the two gear levers to fill and the steering wheels is fitted to the separate steering column that extends to the chassis mounted steering box. The seats are in three parts each and the floor has subtle tread plate included to give a good overall appearance.

Added to the fenders are the pioneer tools with moulded on clips, the two front head lights with clear lenses and two part Notek light, the width indicator posts with a mirror on the left post.

Under the left fender is a three part exhaust muffler with the end of the short pipe hollowed out for a better appearance and two bumper bars are added to the front.

The engine compartment hood is in three parts, the central top hinged panel and the two side L shaped side panels that allow you to show these open if you wish. The side panels have very nicely moulded open louvers for an excellent appearance, there is some flash in the louvre opening that needs to be carefully removed to fully open up the louvers but this is quite thin and easy to remove with a sharp #11 blade. Smaller fittings added to the hood doors are side grab handles and the securing 'T' clip all moulded quite finely as well as small etched brackets on the top of hood panels.

The front radiator coaming has an opening for the radiator which is a separate part added from inside with fine grill texturing as well as an etched number plate added to the lower front. The fit of the radiator coaming is little vague and care is needed to fit this correctly to line up with the folding hood panels, temporarily fitting the hood side panel as you attach the coaming will help getting the correct height for the coaming.

The top hood panel fits between the front radiator panel and the firewall with all the panels fitted either side. The fit was good but there may be some minor trimming needed depending on the proper location of the radiator coaming and firewall. You can show the side hood doors open there is nothing inside but it's all ready for a resin engine from the likes of CMK or SKP?

A separate canvas cover is supplied for the cap should you wish to add a 'roof' but as the cab is fully exposed offers potential to fully detail up if you so wish. You should not that the rear support for the canvas roof is attached to the front of the rear cargo tray so you can't add the rood until after final assembly of the cab and tray.

The fit of the cab to the lower chassis is very good with small locating pins resulting in no filler or trimming being required.

The side and rear panels have the vertical hinge brackets finely moulded and these allow you fit the panels raised or lowered as you wish for travel or unloading dioramas. There are also very small securing clips for the folding panels that will need care removing the fine mould seam before fitting.

Added to the underside of the floor are long mounting beams for fitting to the lower chassis and there are locating recesses on the floor underside to make for a good alignment with the the chassis frame.

On the inside are two wooden bench seats with backrests also with nice wood grain free of pin marks plus the upper front wood paneling, rear and top supports for the canvas cover often seen fitted but the cover itself is not included in the kit. We can assume this will be produced in aftermarket resin before too long hopefully in both full cover and partially folded to allow the insides to be seen?

Other smaller fittings to the cargo tray are the rear number plate bracket and tail light and two pioneer tools which have moulded on tool clips added to the real gate.

The fit of the assembled cargo tray to the lower chassis is spot on and trouble free and this allows you to paint the sub-assembly separate and add later in the final assembly.

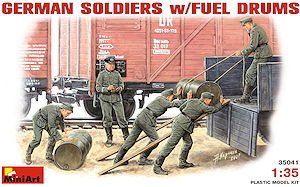

The kit includes four figures loading cargo into the rear and one officer which are from the Miniart figure set German Soldiers w/fuel Drums (Set #35041).

The kit includes four figures loading cargo into the rear and one officer which are from the Miniart figure set German Soldiers w/fuel Drums (Set #35041).

Each figure has 8 or 9 parts in light gray plastic with separate legs, torso, arms, hands, heads and head gear. They all wear standard gray/green tunic over trousers and black leather boots with head gear ranging from field caps, forage caps and officer caps. The only weapons included is the Officers Walther holster and there is no other person gear included.

Detail on the uniforms is nicely done for plastic figures with quite well defined pockets, lapels, and fabric folds and should paint up nicely to include in a diorama scene with the sWS.

Assembly of the figures is straightforward with just the usual moulding seams to be removed, care will be needed not to damage any of the detail of folds when removing these but there shouldn't be any real problems.

Also included is two 200L fuel drums in two halves and separate top lid, the detail is again crisply done on the drums with just the join seam to be eliminated after assembly, the box art shows the drums being loaded into the sWS by way of wooden ramps and ropes but you will have to supply these items yourself as they aren't included in the kit, not that this will be a major problem.

The inclusion of the figures id a nice bonus to go with the sWS for a ready made scene.

|

|

There is very little cleanup required and the fit of the parts very good overall with the front wheels and running gear/track being especially well done apart from the road wheel issue as above.

Apart from this the sWS itself is a standout model and a marked improvement over the aging Italeri offering and should find its way into many a diorama.

Highly recommended

Click on thumbnails for larger view

Detail images

Close new window to return to review

| Büssing's schwerer Wehrmachtschlepper (sWS), armored and unarmored variants Nuts & Bolts Vol.41  |

mittlerer Zugkraftwagen 5t (Sd.Kfz.6)

and Schwerer Wehrmachtsschlepper Panzer Tracks No.22-3  |

Halftrack Vehicles of the German Army 1395-1945 Schiffer Military History ISBN: 0-88740-758-7  |

German Medium Half-Tracked Prime Movers 1934-1945 Schiffer Publications ISBN: 0-7643-0263-9  |

Thanks to Lion Roar/Great Wall Hobby for the review kit.