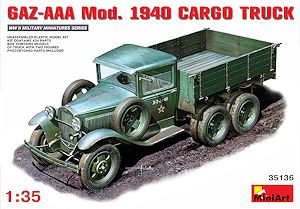

GAZ-AAA Mod.1940 Cargo Truck

Miniart 1:35 Scale Kit #35136

Review by Terry Ashley

The kit consists of:

398 parts in light grey plastic

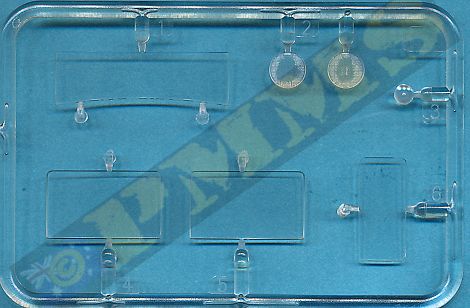

7 clear plastic parts

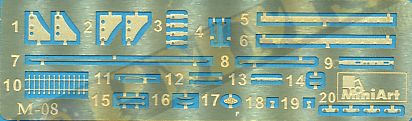

42 etched brass parts

15 additional figure parts

16 page instruction booklet

The quality of mouldings is very good overall with few if any visible pin marks and just a minimum of flash although the smaller parts on the two Fb sprues have considerably more flash than the rest of the parts and needs a lot more clean-up. The main clean-up is with the usual mould seam lines and those on the small and thin parts need care while removing, also the sprue attachments on some parts needs care removing to avoid damage to the parts. A few of the small parts were actually broken on the sprues and needed repairing before use. Oddly the same parts were broken in the same places in all three kits I have which would indicate some stress on the parts, but they were easily glued back together so it was only a minor hiccup.

Dimensionally the kit measures out well against available plans and data in the Tangograd and Tank Power books listed below with the details matching period photos and data very well indeed although the number of parts doesn’t make for straightforward assembly in some areas, most notably with the suspension where there are some traps for the unwary. With the build below I have only assembled the main structures to test the fit etc. with all the smaller items such as headlights, bumpers, door handles, wipers and the hood and rear tray latches plus the etched parts still to be added, I also assembled some sub-assemblies differently than indicated in the instructions as I found a couple of areas where there is potential for problems if not careful. It is of course up to the individual if they want to follow this or build as per instructions, the variations are just suggestions.

The two chassis frames join together with several cross members and you must ensure the front cross member (part A83) is set perfectly at right angles to the chassis frames as this has a direct bearing on the location of the radiator which in turn the fit of the engine hoods, more on this below. You also need to ensure the chassis assembly is perfectly square and level before the glue dries as everything else in the kit fits to the chassis and this must be done correctly to avoid follow on issues.

Assembling the rear differentials/suspension is a little tricky due to the many separate parts, you should firstly glue (and let dry) the spring supports (parts Fb24, Fb25) to the respective axles (parts Fb11, Fb12) taking careful note of the orientation of the axles. When fitting the axles to the central differentials you must ensure the spring supports are positioned perfectly vertical to the top of the differential, any slight variation off the vertical will affect the fit of the spring units later.

The double leaf spring units are best assembled and glue allowed to dry prior to fitting to the axles as this will make things easier during final assembly of the suspension. Also note the exploded assembly instructions showing the fitting of the leaf springs to the axles has the leaf springs all upside down and transposed and will confuse things completely if not careful? Firstly they have transposed the sub-assemblies 9 and 10 (10 should be at the top and 9 at the bottom of the illustration in step 13) and the mounting brackets (parts Fb22) are shown on the inner curve of the axle 10 when it should be on the outer of the spring curve as in the other illustrations.

If this sounds even more confusing it’s best to refer to the fully assembled illustration on the left of page 4 for the correct appearance of the assembled suspension. Also the bracket on leaf spring 10 is numbered Fb2 but in fact should be Fb3, Fb2 being the bracket for leaf spring assembly 9.

When assembling the differentials I firstly glued the joining drive shaft (part Bb5) and let the glue dry as this will set the diffs at the right spacing and ensures the differentials are aligned correctly before you fit the spring units. The drive shaft will have to be cut away again to fit to the chassis but more on that below.

When fitting the differentials and leaf spring units together the ends of the springs may not align precisely with the locating pins on the spring supports if these were not set perfectly vertical during the earlier assembly as mentioned above. But the important thing is for the spacing of the axle stubs to be equal both sides and the correct alignment of the axle stubs horizontally not so much that the springs sit precisely in position within the brackets, if that all makes sense? Also let the glue dry on this sub-assembly before fitting the unit to the chassis frames.

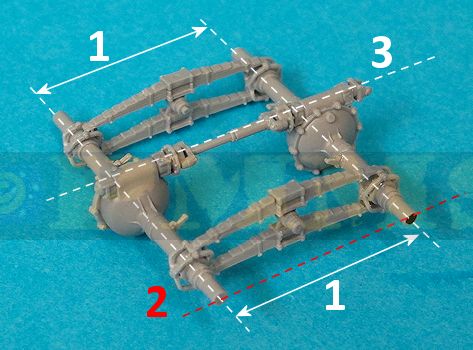

and perfectly level (2), also the central differentials/driveshaft should also be level (3).

Once the glue has dried on the suspension sub-assembly and you have ensured everything is aligned correctly the drive shaft (part Bb5) will have to be temporarily cut-away to allow the assembly to fit over the chassis cross members and then re-attached. This may seem a bit odd in not fitting as per the instructions but I found making sure the alignment of the axles was perfect before fitting to the chassis aided the wheels to sit evenly after fitting, the springs will flex out enough to fit over the chassis locating lugs without any problems.

Once the differential/suspension unit is attached to the chassis and left free to pivot the drive shaft (part Bb5) was re-attached but the shock absorbers (parts Fb16) and forward drive shaft (part Bb1) were left off until the front wheels were fitted later to ensure all six wheels sit evenly on the ground.

The front suspension is quite straightforward but there are some small parts that need care during assembly, the attachment points for the diagonal leaf springs are very delicate and will break if too much pressure is put on the suspension after assembly so take care. There are additional steering rods added between the suspension and chassis but the wheels are not designed to be steerable, you can position them at an angle to animate the front wheels but they are fixed in whatever position you choose. The assembled front suspension is then attached to the chassis cross member (part A83) and this should be left to dry completely before fitting the brake drums of wheels to ensure it stays where it should.

There are numerous other smaller parts added to the chassis such as the fender supports, rear tail light assembly with etched parts for added detail as well as the front bumpers and rear tow hitch. Overall the chassis and suspension parts fit well but there is potential for problems if not careful with the rear suspension alignment and the position of the radiator as indicated above.

The radiator is made up of two main parts with a separate top filler cap as well as a small etched name badge on the front. The detail on the radiator mesh is quite subtle and assembly straightforward but you shouldn’t glue the radiator to the chassis cross member (part A83) at this stage. This is because as mentioned above the position of the radiator dictates the proper fit of the four separate engine hood sections so you should leave the radiator off until after fitting the cab and then use the hood parts as guides to get the radiator in the perfect position as any small miss-alignment of the radiator will see the hood doors not fit correctly.

Assembly is straightforward really with parts C1 to C3 joined in one sub-assembly and C4 to C7 in another sub-assembly, the first sub-assembly (C1 to C3) is then added to the front of the wheel rim and sub-assembly (C4 to C7) to the rear of the rim, note the locating holes will only fit one way, so don’t force it, if the fit is not precise just turn the tyre section around till it does.

Take note of the different rims for the front and two duel rear wheels during assembly, once the wheels are assembled the two rear wheel rims can be joined to form the duel wheel arrangement. The tread pattern has excellent definition but a light sanding with wet-dry will ensure the tread is nice and even without any lumps or bumps. The brake drums and wheels can be added to the axles and then with all six wheels sitting evenly on the floor the remaining rear suspension shock absorbers and linkages can be glued in place to keep everything aligned.

1-3 assembly added to outside of wheel rim disc then 4-7 assembly added to rear of wheel disc.

Note the small lugs and holes only align one way so don't force the sections together, just turn the tyre section around

till it fits neatly into place, this will ensure the proper tread pattern alignment.

Image of assembled front wheel.

Image of assembled rear duel wheel assembly. Note both sit evenly at ground contact as per the review text.

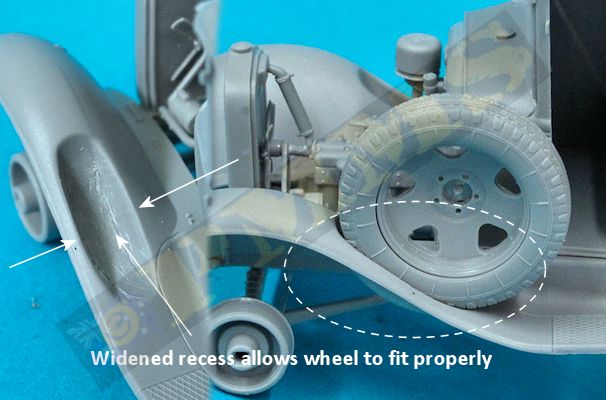

Unfortunately there is a fit issue with the spare wheel into the fender recess where the recesses are not wide enough for the wheels to sit into the recess correctly and you will need to widen the centre section of each recess. Some careful knife work is needed due to the fender and recess contours and I used a curved #10 blade to carefully trim away the required amount of plastic and test fitting the wheel along the way will determine the amount of trimming needed.

Fender recesses are not wide enough for the spare wheel to fit properly

and will need to be widened for the spare to sit into the recess correctly.

With the recess widened the spare will sit properly as intended.

Once these modifications have been done to the recesses the spare wheels can then be added with the rear mounting bracket positioned against the cab wall.

Extreme care is needed when gluing the upper cowling (part A97) to the inner instrument panel (part A38) and in turn the windscreen frame (part A101) plus the two side body panels (parts A39, A40) as there is potential for miss-alignment and unsightly gaps at the sides if not careful assembling these parts. It also helps to add the firewall (part A66) at the same time to ensure the side body panels are correctly positioned, but with due care the fit is good.

Once this assembly has dried the clear windscreen with additional etched parts for the side brackets and windscreen wiper can be added, note the windscreen can be fitted closed or open and the side etched brackets fitted accordingly. There are also additional detail items added to the firewall as well as the inside driver’s foot pedals and gear levers as well as the seat cushions on the floor frame and rear wall. The separate instrument cluster has a very small plastic switch added and the two part steering column and steering wheel can also be added.

When fitting the rear wall and roof it’s advisable to temporarily fit the doors to ensure the correct alignment of the wall/roof, the doors have additional small door handles and window winder handles and these need care in handling being very small but add excellent detail definition to the doors. The clear windows can be fitted closed or cut down to show partially opened windows if you wish and you can choose to glue the doors in the open or closed position as you wish.

Obviously the cab interior would need to be painted along the way and the completed sub-assembly can then be added to the chassis with two small lugs under the cab matching to those on the fenders for the proper alignment which shouldn’t pose any problems.

Once the cab has been attached to the chassis you can then proceed to glue the radiator in place on the chassis cross beam using the two hood side panels as ‘spacers’ to ensure the proper alignment with the radiator in place. The hood side panels have the louver slits moulded with fine gaps but you may want to open these a little more with a fine #11 blade to improve a little, the two top hood parts have inner hinges that fit together precisely along the centreline but the inner hinges on the lower edges and those on the side panels are best cut off as these just seem to hinder the panels mating together properly.

You can position the hood doors closed or folded open to show off the engine should you wish and there are more very small grab handle and latch parts added to the lower hood doors for excellent detail.

There are also the very finely moulded head light mountings and two part head lights with clear plastic ‘glass’ as well as the thin bar added between the fenders with the three part horn added and this delicate detail gives and very good air of finesse to the model but of course needs careful handing as they are also quite fragile.

On the underside of the floor are six small plastic hooks, the cross support beams and rear storage box parts that all fit perfectly without problems as do the upper sides, the central cross beam is actually added to the chassis and not the underside of the tray to make fitting the tray to chassis easier. The side panels have additional small plastic and etched brackets added and the rear gate can be fitted raised or lowered as required for a fairly simple and straightforward sub-assembly that then fits neatly to the chassis without problems.

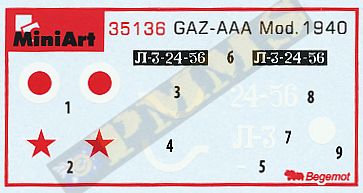

The four options are:

- Unknown unit, German service, Eastern front 1941.

- Unknown unit, German service, Eastern front 1942.

- Unknown unit, Red Army, Winter 1943

- Unknown unit, Red Army, Summer 1942.

A couple of the areas need care as there is scope of miss-aligned parts if not careful such as the cab sides/top cowling and the fairly complicated rear suspension but due care should avoid any major problems.

The kit builds into a superb model of the GAZ-AAA Mod.1940 truck but is not for the inexperienced modeller due to some fairly complex assembly sequences and the fine parts included with the model applicable to many situations and scenarios as it was in service for much of WWII.Rating 9/10

Click on thumbnails for larger view

Build Images

Sprue detail images

| Soviet Trucks of World War 2 Tankograd Soviet Special No.2007  |

Sowieckie samochody pancerne Vol.II Tank Power Vol.XXXII Wydawnictwo Militaria No.256  |

and

and  for

the review kits.

for

the review kits.